Choosing the right packaging for your product can make all the difference in terms of functionality, usability, and customer experience. If you’re considering pipette packaging, it’s essential to assess whether this option suits your product type, volume, and the needs of your users. Here’s a quick guide to help you make an informed decision.

What is Pipette Packaging?

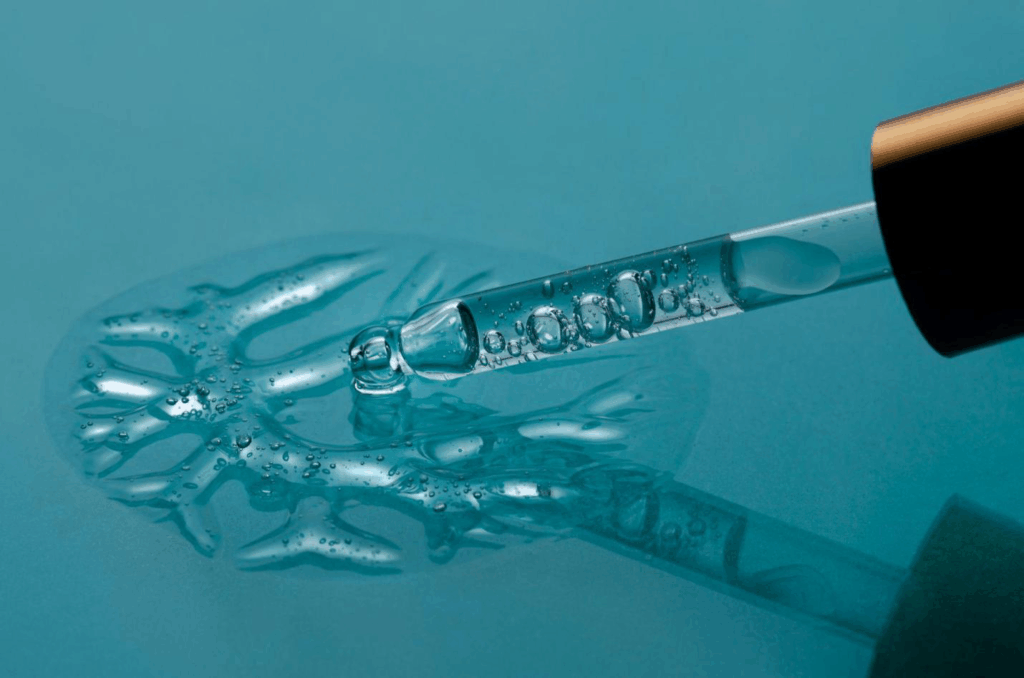

Pipette packaging involves using a small, controlled delivery system to dispense liquids. Commonly used in industries like pharmaceuticals, cosmetics, and chemicals, pipettes allow for accurate dosing with minimal waste. This packaging solution is ideal for liquid products that require precise measurement and application.

Industries That Benefit from Pipette Packaging

Several industries can benefit from pipette packaging, especially those dealing with small quantities of liquid products. Here are some key industries to consider:

- Pharmaceuticals: Pipettes are widely used in the pharmaceutical industry for dispensing medication, especially in liquid form. They allow for precise dosing, which is critical for patient safety.

- Cosmetics and Skincare: For products like serums, oils, and other skincare solutions, pipette packaging allows consumers to control how much product is dispensed, ensuring the right amount every time.

- Chemicals: Industries dealing with chemicals or solutions that need to be applied in small amounts, such as adhesives or cleaning agents, can benefit from pipettes’ precision.

- Food and Beverage: Pipette packaging can also be used in food and beverage applications where small, measured amounts of liquid ingredients are necessary.

Viscosity Compatibility

One of the critical factors in deciding if pipette packaging is right for your product is the viscosity of your liquid. Pipettes are ideal for products with low to medium viscosity. Here’s a breakdown of how pipettes handle different viscosities:

- Low Viscosity: Pipettes excel at dispensing low-viscosity liquids, such as water, oils, and certain chemicals. Their precision ensures that the right amount is dispensed without spillage.

- Medium Viscosity: Products like gels, lotions, and some pharmaceuticals can also be dispensed with pipettes, though the flow rate may need to be adjusted to ensure smooth dispensing.

- High Viscosity: For thicker liquids like pastes or heavy adhesives, pipette packaging may not be the best option. In such cases, a different type of packaging, such as bottle filling services, may be more suitable.

Use Cases for Pipette Packaging

Pipette packaging is best suited for products that require controlled dispensing, especially when accuracy is paramount. Some common use cases include:

- Medical Dosing: Pipettes are perfect for dispensing precise amounts of medication or other medical liquids, ensuring correct dosages for patient safety.

- Cosmetic Applications: For beauty products like face serums or oils, pipettes allow for accurate application, giving consumers better control over how much product is used.

- Chemical Additives: When dispensing chemicals or small quantities of cleaning solutions, pipettes minimize waste and ensure accurate application, making them a reliable choice for chemical manufacturers.

- Food and Beverage Ingredients: Pipettes can be used to dispense flavorings, oils, or other liquid ingredients in the food and beverage industry, offering precision when mixing or adding ingredients.

Quality Packaging Services with Custom Pak Illinois

At Custom Pak Illinois, we offer a range of contract packaging services to meet the needs of businesses across multiple industries. Whether you’re looking for contract tube filling services, bottle filling services, or pouch filling contract packaging, we have the expertise and technology to deliver high-quality packaging solutions for your products.

When considering pipette packaging, it’s essential to assess your product’s viscosity, intended use, and the level of precision required. Custom Pak Illinois is here to help you choose the right packaging solution for your business. Contact us today to learn more.